TURN-KEY

Turn-key projects covering integral engineering design and installation for

Production of milk powder

Production process of fruit juice and powder

Production of liquid milk

Production of ice cream

Production of plant protein beverage

Production of fruit and vegetable juice

TUBULAR UHT STERILIZER

Tubular Ultra High Temperature (UHT) Systems designed for processing with standard UHT food, dairy, beverage etc.

Capacities: 1,2,3,4,5,6,8,10 tons per hour

CIP and PLC system

Pre-assembled and factory-tested

เครื่องฆ่าเชื้อระบบ UHT เริ่มจาก product supply unit รับนำ้นมมาเพื่อ process โดยผ่าน tubular sterilizer ซึ่งประกอบด้วย tubular heat exchangers แต่ละท่อทำหน้าที่เฉพาะ regenerative > main heater > holding section > heater/cooler โดยมีโฮโมจีไนเซอร์ ปั้มนมผ่าน heat exchanger และควบคุม capacity of the installation โดยมี metering unit control panel และ control system

Customer references: Bright Dairy (40% fresh milk share), Jilin Guangze, Mengniu Dairy etc.

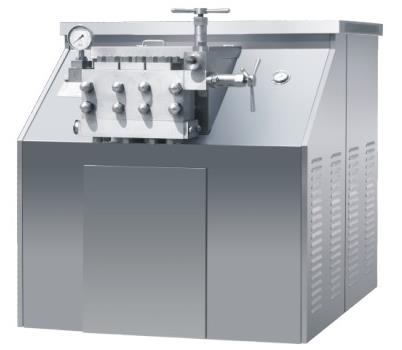

LARGE-SCALE HOMOGENIZER

Hydraulic controlled pressure adjustment and manual pressure adjustment

Fully closed stainless steel structure

Modular outer cover enables rapid assembly and dis assembly and facilitates maintenance and servicing.

Homogenization is a mechanical process used to reduce the size of the fat globules size from an average of 3.5 µm in diameter to below 1 µm.

Homogenization temperatures normally applied are 55–80 °C, and homogenization pressure is between 10 and 25 MPa (100 – 250 bar), depending on the product.

HIGH PRESSURE HOMOGENIZER

HOMG Series

Pressure: there are 25, 30, 40, 60 and 70MPa five series.

Flow rate various from 100 liters/hour to 5 tons/hour

Homogenization is a mechanical process used to reduce the size of the fat globules size from an average of 3.5 µm in diameter to below 1 µm.

Homogenization temperatures normally applied are 55–80 °C, and homogenization pressure is between 10 and 25 MPa (100 – 250 bar), depending on the product.