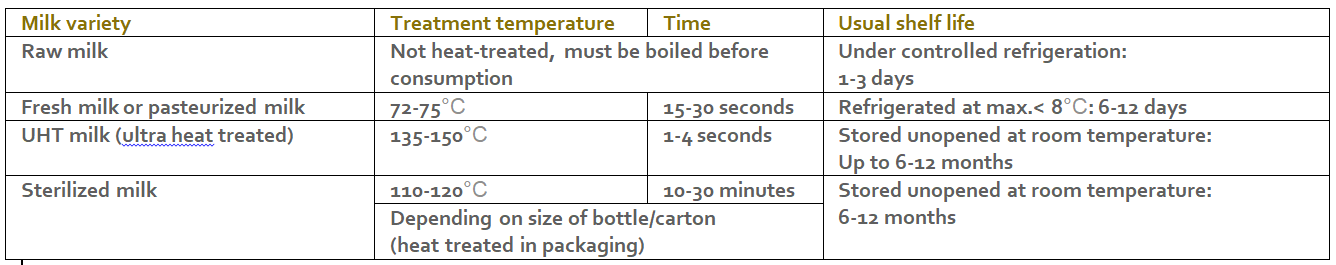

HEAT TREATMENT & SHELF LIFE

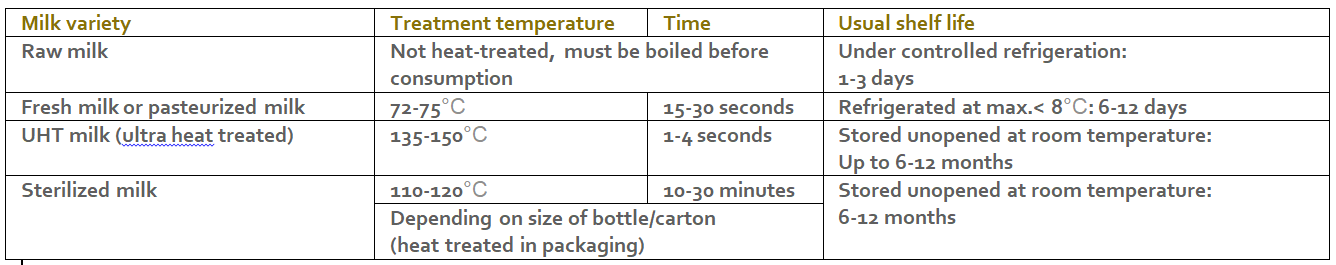

กรรมวิธีให้ความร้อนในผลิตภัณฑ์นม มีวัตถุประสงค์ในการทำลายจุลินทรีย์และเอนไซม์ ที่จะทำให้นมบูด เสียรสชาติ และมีอายุบนชั้นวางจำหน่ายสั้นลง นำ้นมดิบมีสภาวะที่เหมาะสมต่อการเจริญของจุลินทรีย์เป็นแหล่งของการติดเชื้อ ต้องผ่านกรรมวิธีให้ความร้อนโดยใช้เวลาและอุณหภูมิที่เหมาะสมจึงสามารถบริโภคได้

ระบบพาสเจอไรซ์โดยให้ความร้อน 72-75 องศาเซลเซียส นาน 15-30 วินาที สามารถเก็บในตู้เย็นได้ 6-12 วัน

ระบบยูเอชที โดยให้ความร้อน 135-150 องศาเซลเซียส นาน 1-4 วินาที สามารถเก็บโดยไม่ต้องใส่ในตู้เย็นได้ 6-12 เดือน

ระบบสเตอริไลเซชั่น โดยให้ความร้อน 110-120 องศาเซลเซียส นาน 10-30 นาที สามารถเก็บโดยไม่ต้องใส่ในตู้เย็นได้ 6-12 เดือน

PASTEURIZATION

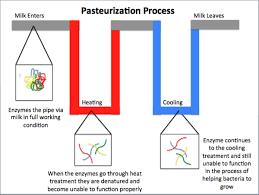

Pasteurization is the heat treatment of a product to kill pathogenic bacteria and reduce enzymatic activity. The purpose is to make the product safe for consumption and to lengthen product shelf life.

ในการแปรรูปนม อุณหภูมิของนมที่ผ่านกระบวนการทำให้เป็นเนื้อเดียวกันและกระบวนการพาสเจอไรซ์ จะลดปริมาณเชื้อจุลินทรีย์ที่ไม่ต้องการ และทำลายเชื้อจุลินทรีย์ที่ทำให้เกิดโรคทั้งหมด โดยมีวัตถุประสงค์ที่ทำให้ผลิตภัณฑ์ปลอดภัยสำหรับการบริโภคและเก็บรักษาได้นานขึ้น

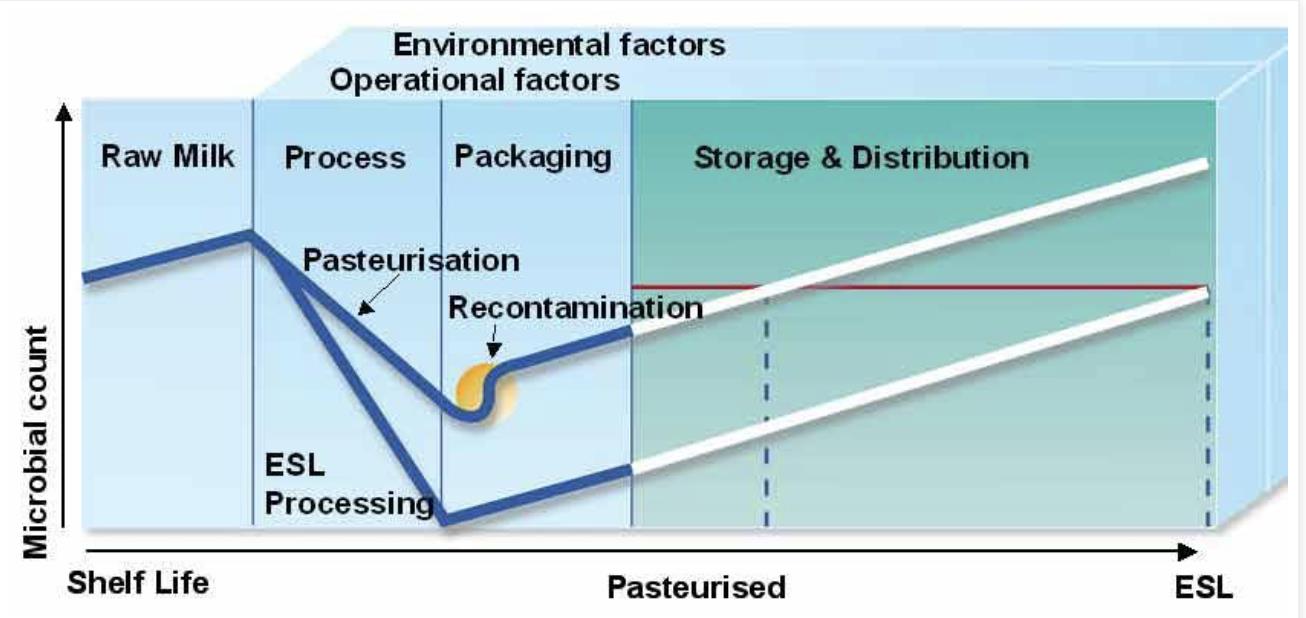

ESL MILK

ESL (extended shelf life) milk is labelled as ‘longer-lasting’, but just like regular fresh milk, it must be stored in the chiller or in the fridge. An unopened bottle or carton of ESL milk stored in the fridge (max. 8℃) will keep for 21 to 30 days. In term of shelf life, ESL milk is therefore positioned between traditional fresh milk and UHT milk.

นมที่ผ่านกระบวนการทำให้เป็นเนื้อเดียวกันและกระบวนการ ESL จะลดปริมาณเชื้อจุลินทรีย์ได้มากกว่านมพาสเจอร์ไรซ์ธรรมดา นม ESL ออกแบบให้มี Superior hygienic design เทคโนโลยี่การบรรจุป้องกันการติดเชื้อ recontamination จากการบรรจุ (filling environment)

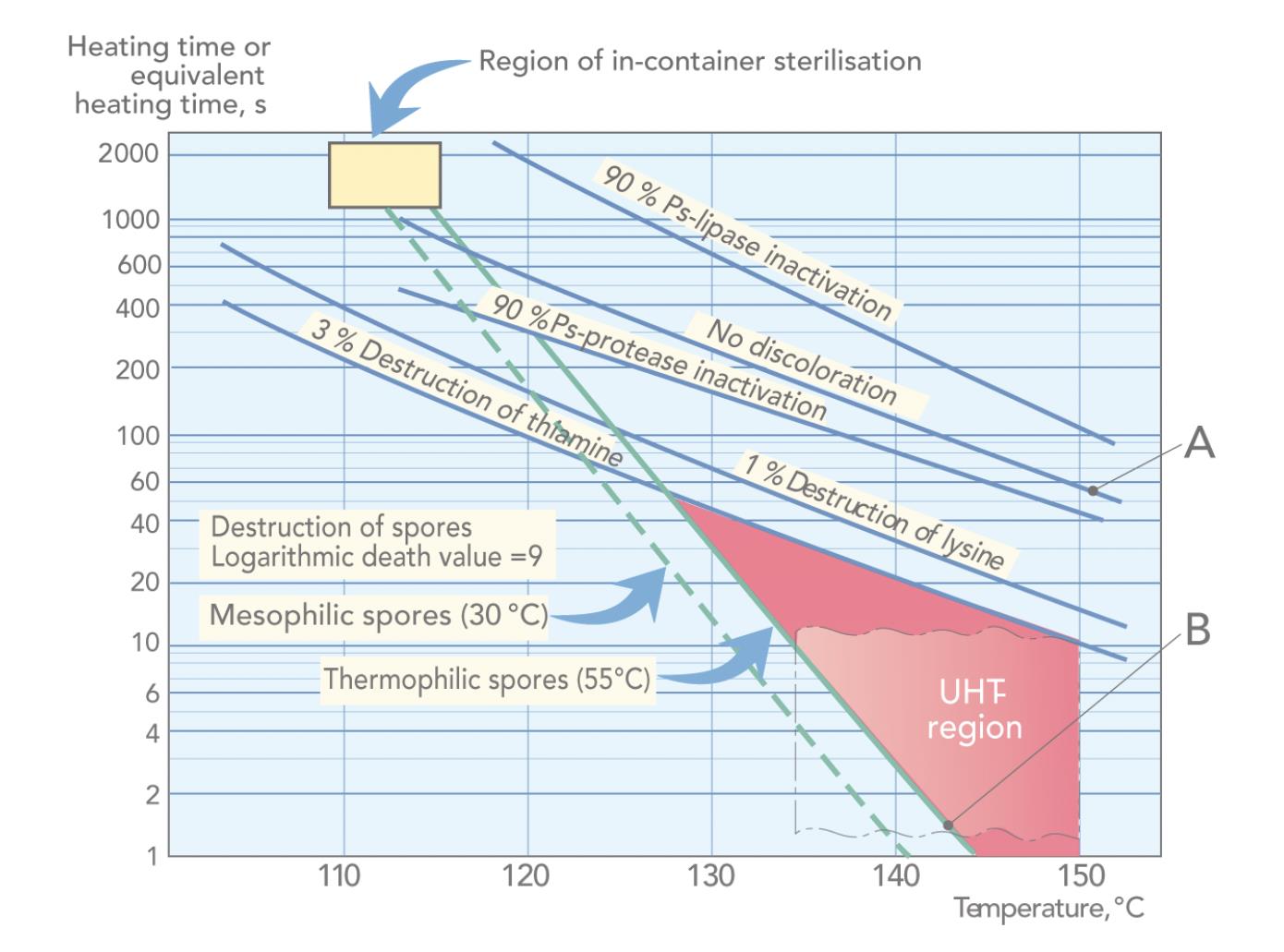

UHT TECHNOLOGY

Used for the sterilization of low acid foods, UHT treatment involves heat ing the product to over 135℃. It destroys all microorganisms, making the end product suitable for ambient distribution.

กระบวนการการฆ่าเชื้อในผลิตภัณฑ์โดยการให้ความร้อนสูงเพื่อทำลายจุลินทรีย์ทั้งหมด และลดความว่องไวของเอนไซม์ที่ทนความร้อนส่วนมาก ทำให้ผลิตภัณฑ์ที่ผ่านการฆ่าเชื้อสามารถจัดเก็บได้นาน โดยไม่เสื่อมคุณภาพและไม่จำเป็นต้องแช่เย็น ทำให้การกระจายสินค้าและผู้บริโภคได้รับความสะดวก

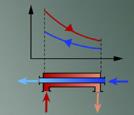

HEAT EXCHANGERS

The exchange of heat between the product and the heating or cooling medium is effected via the plate or tube walls of the plate or tubular heat exchangers, without the product coming into contact with the heating or cooling medium.

การแลกเปลี่ยนความร้อนในการผลิตนม สามารถควบคุมอุณหภูมิของนมในขั้นตอนการให้ความร้อนโดยใช้น้ำร้อนหรือไอน้ำความดันต่ำและทำให้เย็นลงโดยใช้น้ำเย็น น้ำแข็ง หรือสารละลายแอลกอฮอล์ เช่น Glycol น้ำนมร้อนที่ออกจากกระบวนการ ยู เอช ที จะนำไปใช้อุ่นน้ำนมที่เย็นนำเข้าสู่กระบวนการอุ่นขั้นต้น น้ำนมร้อนก็จะเย็นลง เป็นการประหยัดพลังงานที่ทำความร้อนและทำความเย็น กระบวนการนี้เกิดขึ้นในเครื่องแลกเปลี่ยนความร้อน พลังงานที่นำกลับมาเวียนใช้ได้ประมาณ 90-95%

CLEANING IN PLACE

Cleaning in place (CIP) refers to all the mechanical and chemical system necessary to prepare equipment for hygienic food processing that are carried out without dismantling the system.

Benefits of CIP:

Improved cleaning results

Material and energy saving

Improved productivity

Cleaning-in-Place (CIP) การทำความสะอาด complete items of plant or pipeline circuits โดยไม่ต้องถอดหรือเปิดอุปกรณ์และผู้ควบคุมเข้ามาเกี่ยวข้องน้อยมาก จะเพิ่มประสิทธิภาพในการทำความสะอาด ลดเวลาการทำความสะอาด ทำให้มีเวลามากขึ้นในการผลิต เครื่องจักรและอุปกรณ์ที่จะทำความสะอาดจะต้องปิด